A key element for long lasting LED: the wire bond material quality

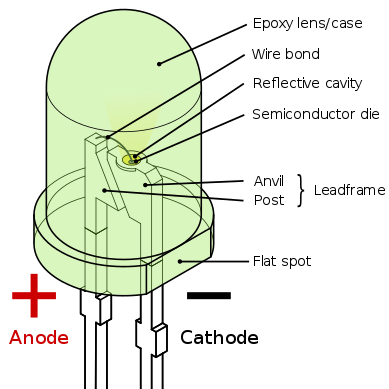

In the selection of a product or a LED supplier some key elements are to look for a long-lasting LED. Among these is the wire bond material, let me explain. In the LED chip itself is a tiny wire, which in comparison to an incandescent lamp does not heat a gas to create light. It is attached to the anvil of the anode, provides current to the post of the cathode where it is pad bonded to the LED wafer. The current excites the wafer and bam! A light source is created. In higher quality LEDs the wire bond is made from gold and infused with beryllium, for rigidity and support.

Don’t get your project jeopardized by a cheaper wire bond component.

Of late, some copper conductive bond wires have appeared, lowering the overall cost of the LED. As a result of this change; open circuit defects, poor pad bonding, oxidation, electrical current strain hardening, and stiffer bond wire on weak support structures often cause failures. It is important to understand, what the LED is made of when you are specifying a project.

Long lasting LEDs using quality materials are crucial for a sustainable broadcasting and Nummax sees to it that we use only the best.

.

LED TECHNOLOGY

- Semiconductor die = Aluminum Indium Gallium Phosphate (AlInGaP)

- UV coated epoxy covers are only coloured for ID purposes = Diffuser / Elliptical / Viewing angle

- Each LED is UV potted vs Silicone

- 350 micro amps of power draw

- 12µ vs 9µ Chips = higher light output with lower energy use

- ∴ more efficient power supplies to 88%

- Anode / Cathode using a gold plated wire bond to heat the semiconductor die